|

An

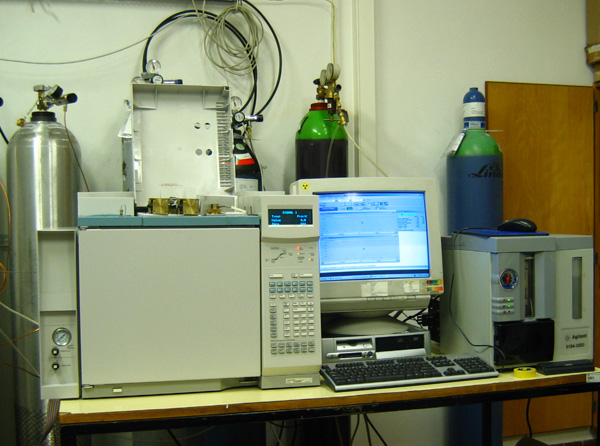

Agilent 6890N gas chromatograph (GC) based analytical

system was installed in Hegyhátsál in 26-27 January,

2006. Air samples are taken from 96m elevation.

Using ECD and FID sensors the mixing ratio of

CH4, CO, N2O and SF6

are monitored continuously.

System

description:

Auxiliary

system components:

Hydrogen

generator: Parker Balston: Mod.: 9090

Air compressor: Jun-Air Mod.: OF-302-25B x 2

Zero Air generator: Parker Balston Mod.: 75-83-220

N2 generator: Parker Balston Mod.:

76-92-220

We had problems with the latter model, since there

was no catalyst for hydrocarbon (especially methane)

removal. To establish the optimal condition for

the N2 generator we dried the compressed

air with an adsorption dryer, Mod.: HL-S0120,

but this did not decrease the methane concentration

in the generated nitrogen. To solve the problem,

we use compressed nitrogen, with purity of 99.99990%

(6.0).

Sampling

system:

Filter

Pump: KNF Neuberger, Mod.: N86ATE (special version)

Rotameter1

Miniature pneumatic supply - constant pressure

and stream splitter

Rotameter2

Dryer at about -90 deg.C

Valco 10 position sampling valve with microelectronic

controller

Summary

of the system:

Instrument

principle: GC

Manufacturer: Agilent

Type: 6890N

Acquired: 2003

Sample flow: approx. 150 ml/min

Reference flow: approx. 150 ml/min

Sample period: 10 mins

Flush time: 0.5 mins

Calibration freq: 12 hours

Target freq: 0.3 hours

Column A: Unibeads+mol.sieve 5A 1/8 inch,4+6 feet

Column B: Hayesep Q 1/8inch 4+6 feet

Measurements stored 6 per hr

Levels: 96 meter AGL

The

GC system in operation at the measurement site

Schematic

diagram of the Agilent 6890N setup (Figure by

courtesy of Cyril Messager, LSCE)

|